Extensometer calibration system

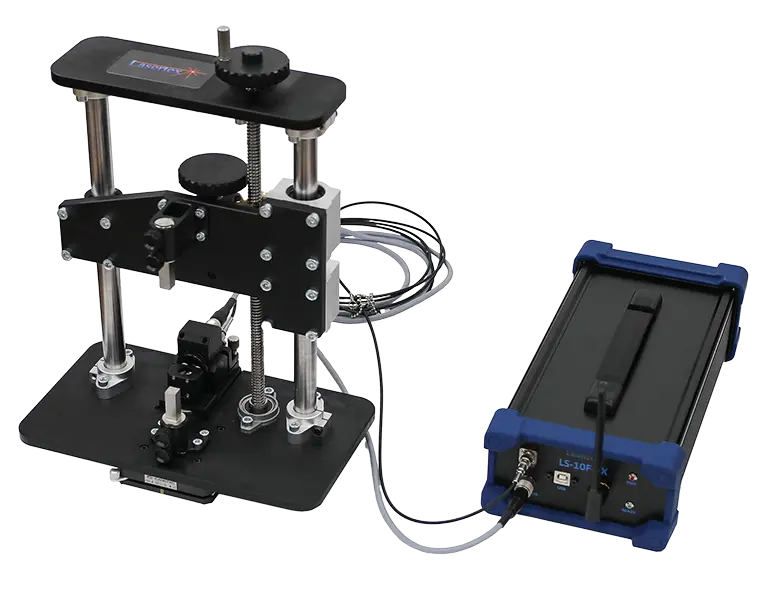

Lasertex LS-10F EX is an extensometer calibration device designed as a special version of Laser encoder LS-10F. This setup suit for calibration traditional clip-on extensometers as well as laser ones. For clip-on extensometers special attachment is used. For laser extensometers there are marking on the device that laser extensometer can lock on and track.

Lasertex LS-10F EX is an extensometer calibration device designed as a special version of Laser encoder LS-10F. This setup suit for calibration traditional clip-on extensometers as well as laser ones. For clip-on extensometers special attachment is used. For laser extensometers there are marking on the device that laser extensometer can lock on and track.

Laser encoder provides high precision measurements. Laser head is integrated into the control module and the beam is delivered to the emitter by optical fibre cable. This setup reduces temperature factor to almost negligible and improves research quality and repeatability.

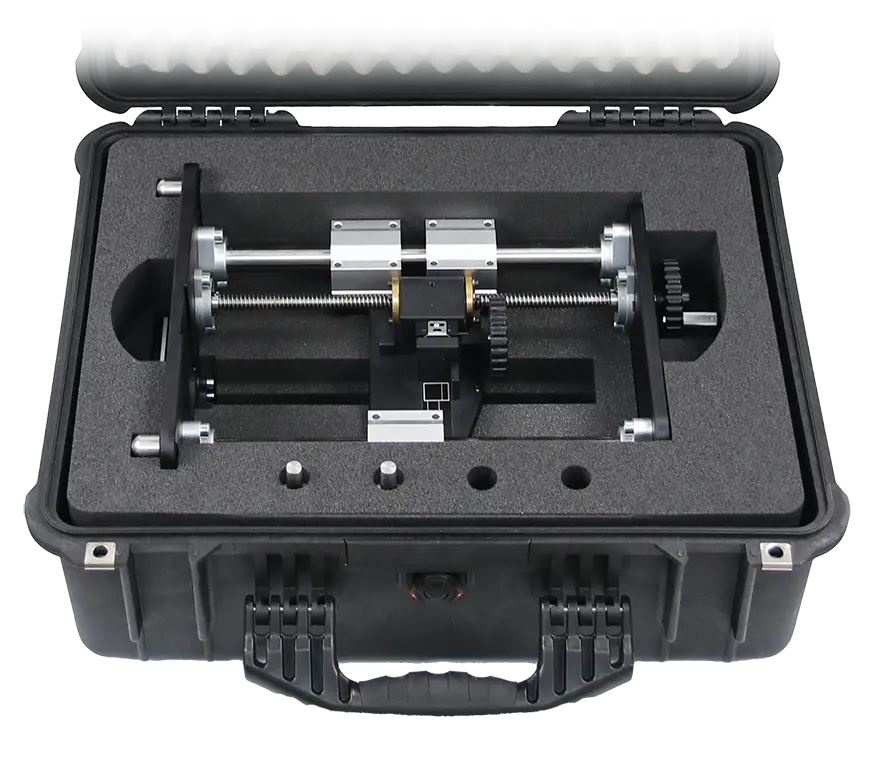

The device is shipped in two reinforced cases to provide protection and ease of transportation. The setup can be used for test in laboratory environment as well as a portable solution for providing outsource service. The device is easy to transport and mount or dismount, that can be an advantage for measurement service provider.

Extensometer calibration device for material testing - features:

- support for operation as a part of a calibration site

- customisable PC software

- wide choice of possible optical configurations

- available drivers for Windows, MacOS and Android operating systems

- configurable digital inputs and outputs for variety of OEM applications

- very high precision operation - 1 ppm accuracy

- high resolution readout available both on the USB and Bluetooth interface

- automatic compensation of environmental changes of laser wavelength

- monitoring of the device operation from PC computer

- Accuracy and Precision: Calibration guarantees accurate and precise measurements from your laser or clip-on extensometers. Measurement accuracy may be impacted over time by environmental changes, wear and tear on the equipment, and other factors. These deviations from the expected values can be identified and fixed with the aid of calibration.

- Standards Compliance: Lots of applications and industries demand adherence to particular rules and regulations. Calibration ensures that your measurement tools are up to par, which is frequently necessary for quality control, product testing, or adherence to industry standards.

- Quality Assurance: Calibration of your measurement equipment is a critical part of quality assurance processes. It verifies that your instruments do function correctly and consistently. Consistently accurate measurements are crucial for maintaining product quality and process reliability.

- Data Reliability: Accurate measurements are necessary to collect reliable data and analyse it. Doesn’t matter if you are conducting research, or quality control, or material testing, having a calibrated helps to ensure that your data is trustworthy and appropriate for making decisions.

- Safety: Inadequate material measurements occasionally result in crucial material failure. Today’s high-tech manufacturing and construction are pushing the limits of the available materials. Extensometer calibration produces accurate measurements that gradually lower the risk to safety.

- Cost savings: By identifying instrument problems early on with routine calibration, you can lower the risk of expensive mistakes or rework brought on by inaccurate measurements. Investing in calibration is more cost-effective than dealing with the effects of inaccurate data.

- Traceability: Calibrations are often performed by accredited laboratories, and they provide a traceable record of the measurements’ accuracy. This traceability is important for audits, compliance, and demonstrating the reliability of your measurements to clients, regulators, or stakeholders. Lasertex offer additional ISO certification of the equipment on demand to obtain traceability for the client who need it.

- Long-Term Performance: Regularly calibrating your instruments may increase their usable lifespan. You can avoid premature instrument failure and the associated replacement costs by quickly identifying and solving issues.

- Confidence in Results: Instruments that’ve been calibrated give users confidence in the outcomes. Having faith in your measurements is crucial for making wise decisions, regardless if you’re working on a manufacturing process, conducting scientific research, or testing products.