The choice of optical elements necessary for squareness measurements depends on the selected measurement method: i.e. 3D or Wollaston. If 3D method is used then the linear optics plus right angle etalon should be used. In this case the necessary components are:

- Laser Head

- Power Supply

- Linear Interferometer IL1

- Linear Retro-reflector RL1

- Right angle etalon RE3D or REW

In the case of the Wollaston type measurement the necessary components are:

- Power Supply

- Wollaston prism WP2

- Wollaston retro-reflector WRP2

- Laser Head

- Right angle etalon REW

For both methods the optional elements are similar:

- USB cable

- Manual Strobe

- Magnetic holder UM2

- Tripod stand

- Air temperature sensor

- Base temperature sensor

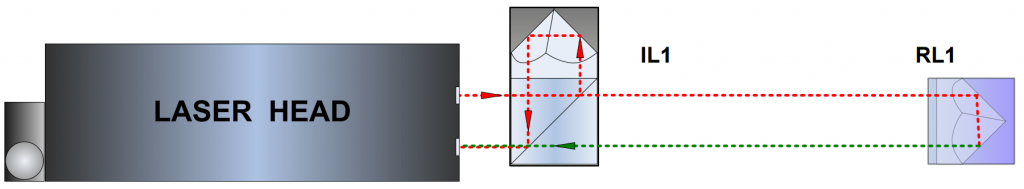

Squareness measurements based on the 3D method require optical elements IL1 and RL1 to be first aligned along the laser beam as shown in the figure below. The element RL1 should be moved. Obtained results of the axis straightness should be saved for further processing.

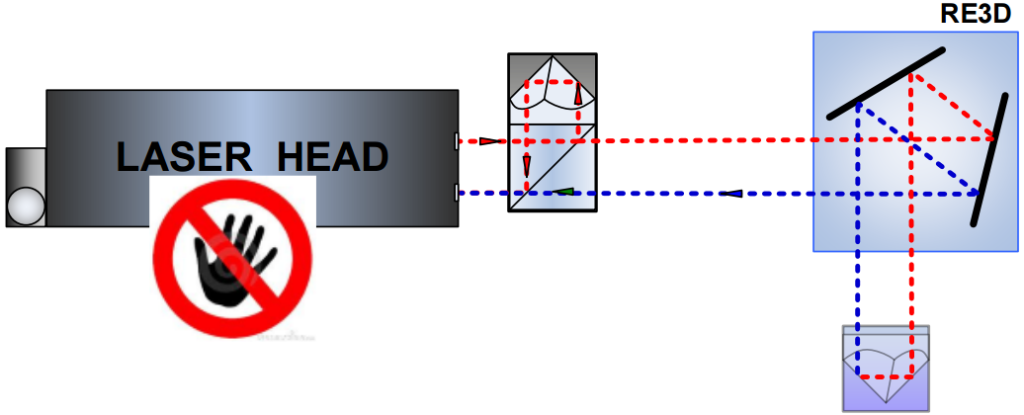

In the next phase of the measurements the beam should be directed to the perpendicular axis with the use of right angle etalon RE3D or REW.

The optical configuration is shown in the figure below. The measurement of the axis straightness should be performed with the movement of the RL1 element.

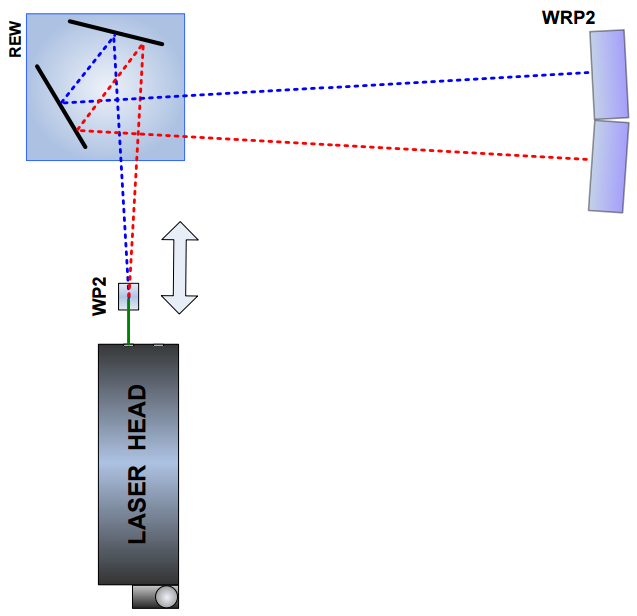

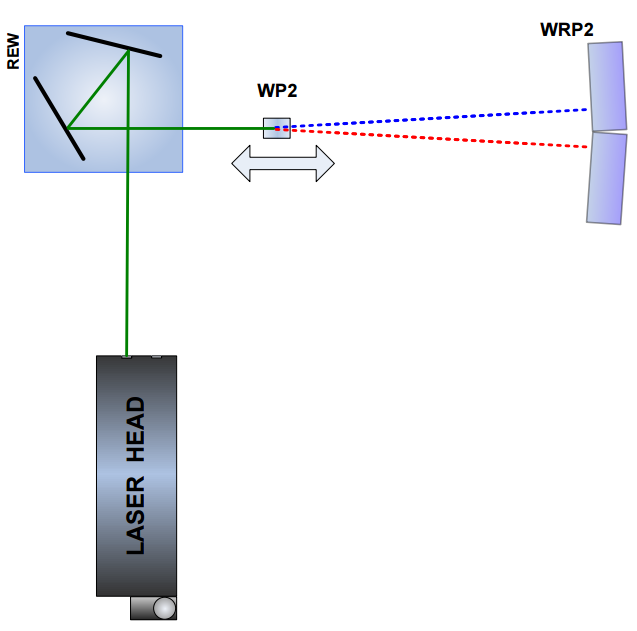

Wollaston squareness measurements require optical elements WP2 and WRP2 to be aligned along laser beam as shown in the figures 10.3A and 10.3B. The beam should be directed to the perpendicular axis with the use of right angle etalon REW. The measurements consist of two parts. In the first part the WP2 is moved between the laser head and the REW prism (Fig. 10.3A). During the second part the WP2 should be placed between REW and WRP2